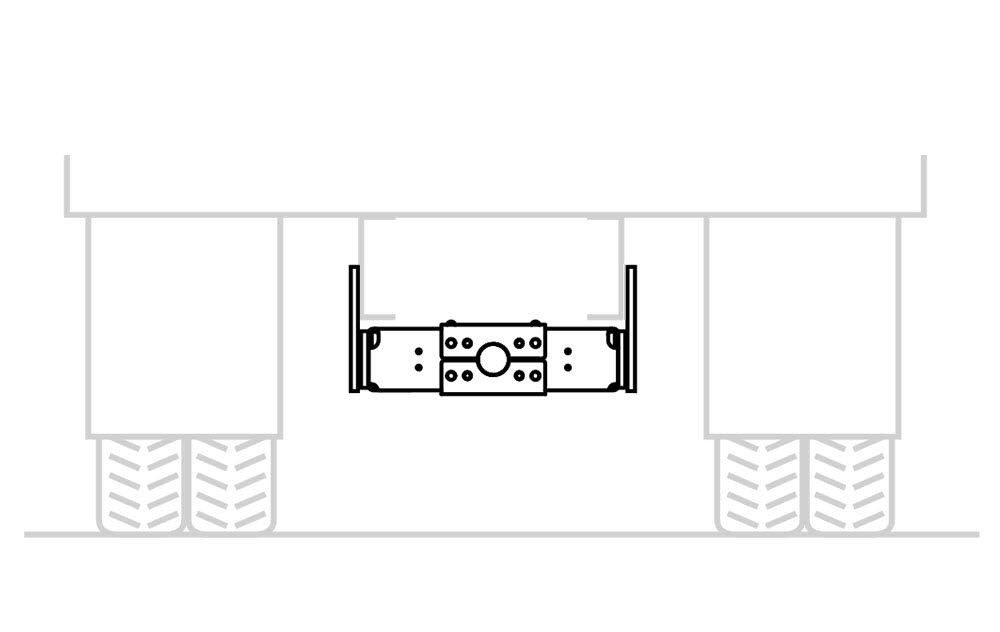

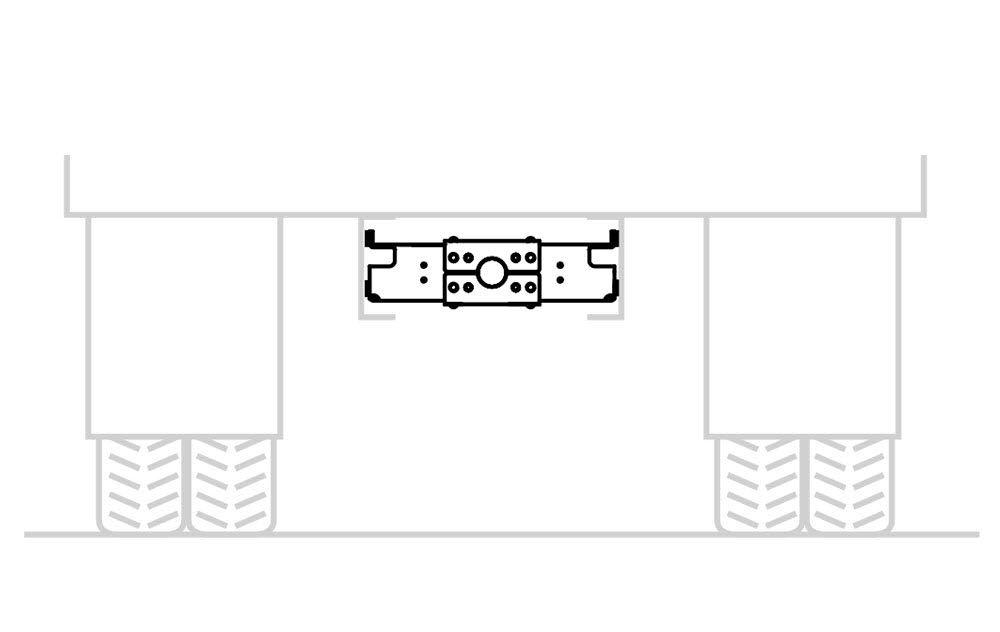

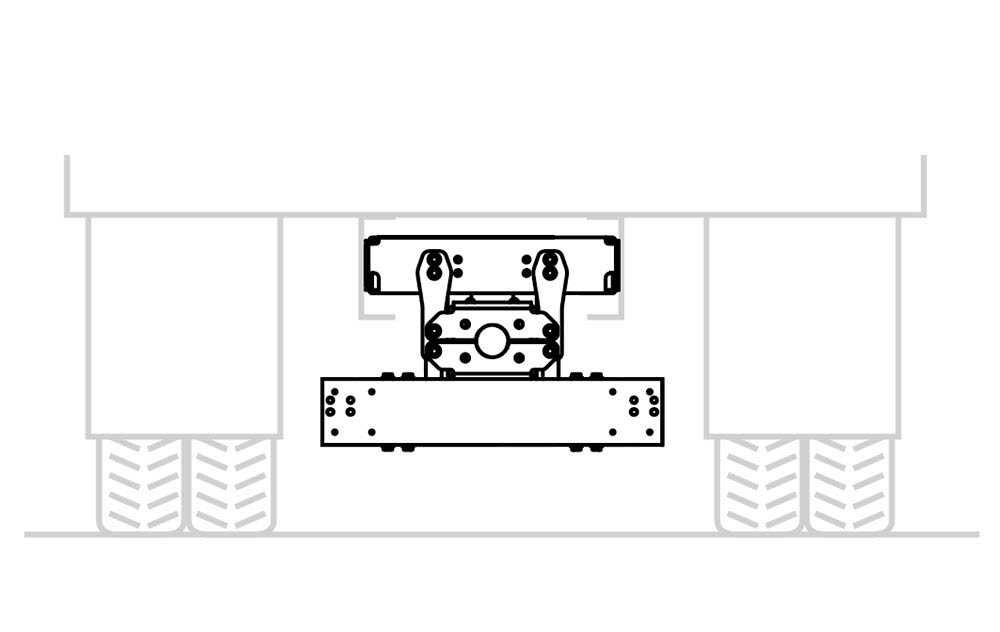

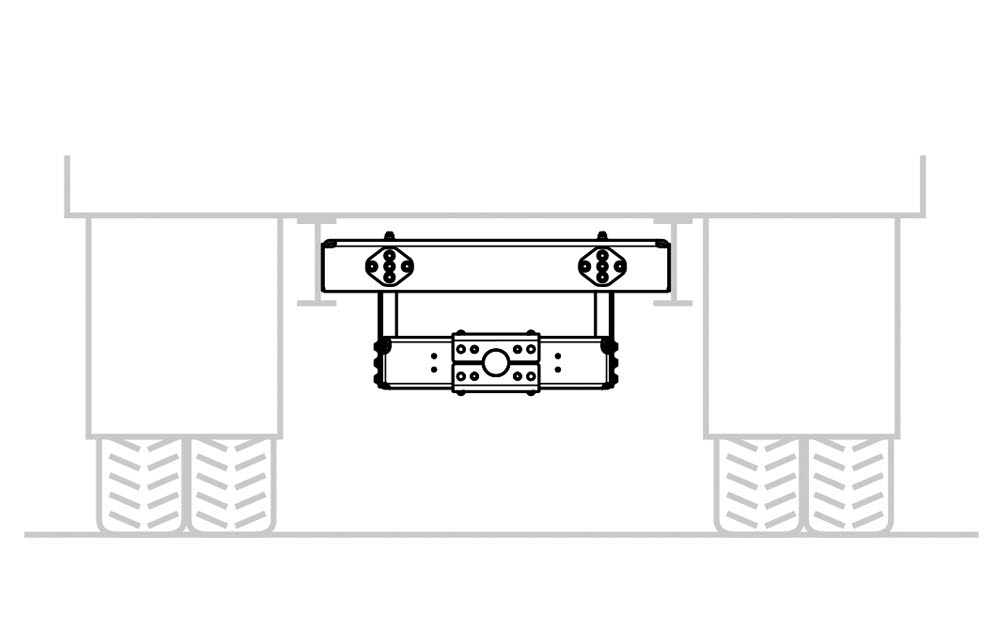

Drawbeam system

VBG’s Cross Member System (CMS) drawbeam system comprises a wide range of standardised components that can be combined to provide a perfect fit. The system reduces the need for modifications when installing the coupling equipment, which makes installation quick and simple. The system is customised for various vehicle manufacturers, and you can get the endplate, coupling, and attachments pre-assembled, which saves you even more time.